Techlion Display

LCD Module Manufacturer

Micro LED Transparent Displays Accelerate to the Market

Micro LED transparent displays have been rapidly gaining popularity since 2024. Lenovo launched the world’s first transparent Micro LED screen concept laptop Think Book, Samsung displayed the first transparent Micro LED TV, VTEAM released a tablet-sized transparent Micro LED screen ……

Micro LED transparent display is one of the innovations in the development of Micro LED technology, from a cutting-edge display technology full of sci-fi color, to the terminal application landing in the business, car, life and other colorful scenes, Micro LED transparent display is accelerating to the public. However, Micro LED transparency still has technical difficulties that need to be broken through.

Contents

- 1 Micro LED is how to become transparent? What are the technical differences with traditional LED transparent screen?

- 2 What technical difficulties need to be overcome to realize transparent Micro LED?

- 3 Micro LED transparent display carries more imagination space

- 4 Micro LED is regarded as the representative technology of new display technology in the future, what is the combination of Micro LED and transparent display technologies? At present, how is the layout of Micro LED transparent display? Is the technology favored by mainstream manufacturers?

- 5 What are the advantages of Micro LED transparent display compared to transparent OLED display technology, and in which fields is Micro LED transparent display more suitable for application? What is the judgment on its market trend?

- 6 The market demand for Micro LED transparent display will be significantly increased.

- 7 Are there application limitations for Micro LED transparent displays? How to balance the display effect and transparency of Micro LED transparent display?

- 8 When Micro LED transparent display terminal products in the major consumer electronics exhibition frequently debut, whether it is a sign of “transparent display” of the exclusive era is coming? How far away from the Micro LED transparent display market demand explosion there is still much road to go?

Micro LED is how to become transparent? What are the technical differences with traditional LED transparent screen?

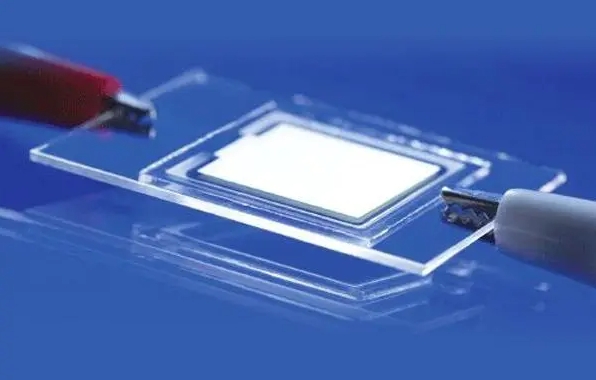

Transparent screen in the traditional LED display application field is not strange, the traditional LED light bar screen has long been large-scale mass production and application. Micro LED transparent display is one of the innovative products of Micro LED technology development, which is fundamentally different from traditional LED transparent screen. Transparent Micro LED is to use Micro LED light-emitting chips on transparent TFT glass substrate to realize high transmittance Micro LED display. Recently, through the innovation of the substrate and other ways, new products such as LED crystal film screen have appeared, and have been successfully applied in the fields of commercial display and advertisement.

Micro LED can be transparent, mainly because Micro LED size is very small, almost transparent, and its use of transparent glass substrate, through the preparation of lines on the glass substrate, and the LED patch to the glass can form a transparent display.

In this process will mainly face several technical difficulties: first, according to the characteristics of the LED Micro LED line and drive special design, but also consider the corresponding circuit compensation and the line for the light transmittance of the impact;

Secondly, the Micro LED perfect pieces to the glass, will greatly test the transfer and welding process, yield and efficiency; Finally, if the LED is too small, the wafer’s luminous efficiency is too poor, will also cause the transparent LED screen brightness is not enough, therefore, how to reach a balance of the above technology is very critical.

Micro LED display technology is on the basis of LED miniaturization and matrix, the size of its individual light-emitting unit is usually in the micron level. Micro LED transparent display principle is the micro LED chip bonded to a transparent substrate, so that the display screen as a whole has the characteristics of transparency. The transparent substrate is a conductive glass or polymer material with good transparency properties. Micro LED chips are usually composed of red, green and blue LED chips, or red and green can be generated by blue light excited quantum dots. Each color can be controlled independently. The brightness and color are changed by controlling the current of the Micro LED chip to present the display content and adjust the display effect.

Micro LED transparent screen is fundamentally different from traditional LED transparent screen. The traditional LED transparent display is mainly LED light bar screen, which can achieve the effect of transparent display by installing behind the glass curtain wall. Later on the basis of the traditional LED light bar screen, through the innovation of the substrate, the industry is also constantly launching new LED transparent screen products, such as the use of transparent flexible film LED crystal film screen. The Micro LED transparent display is on the transparent TFT glass substrate, using tens of microns of Micro LED light-emitting chips, through the COB package, to achieve high transmittance Micro LED transparent screen.

Since 2024, the heat of transparent display has remained high, and many manufacturers have brought their own Micro LED transparent display products to the public.

What technical difficulties need to be overcome to realize transparent Micro LED?

The smaller the Micro LED chip, the easier it is to achieve a better transparent display effect. The pain point of Micro LED transparent display actually does not lie in the process of realizing transparency, but in how to upgrade the Micro LED technology itself. For Micro LED transparent display, there are two main technical difficulties to be tackled.

First, the mass transfer. The traditional LED chip is bonded to the substrate through the Die Bonder machine, its chip size is usually more than 0.1 mm, the precision of the Die Bonder machine in the order of 10 microns. But when the Micro LED chip is tens of microns or even a few microns, it exceeds the precision limit of the Die Bonder machine, and the efficiency is very low. Mass transfer is proposed in this context. Mass transfer has extremely high requirements for transfer quantity, transfer speed, transfer precision, transfer yield and transfer cost.

Since Micro LED has a high pixel density, the number of components and transfer speed required for Micro LED display devices need to be greatly increased compared to other display devices, and the transfer yield is also required to be above 99.9999%. At the same time, the mass transfer cost is extremely high, accounting for about 20% of the total product cost. At present, the industry has developed Micro LED jumbo transfer technology mainly includes viscoelastic stamp, laser stripping, roller transfer, electrostatic, electromagnetic, fluid self-assembly and chemical stripping.

Second, mass detection. As the size of the Micro LED chip reaches the micron level, it is no longer possible to use the traditional probe contact electrode method to supply energy to light up the LED chip, the industry tends to use similar photoluminescence and other non-contact methods to inject energy into the Micro LED, and then its optical and spectroscopic detection, in order to solve the Micro LED miniaturization of the production chain after the process control and yield monitoring problems.

The technical difficulties of Micro LED transparent screen come from the TFT glass substrate itself on one hand, including the TFT device technology to meet the requirements of Micro LED, the high current-carrying capacity of the glass substrate copper cladding technology, etc.; on the other hand, it comes from the fact that the size of Micro LED light-emitting chips is only a few tens of micrometers, which must be used in the mass transfer technology, laser bonding technology, and mass repair technology, etc., but at present, these technologies are still far from mature.

In addition, for large size Micro LED transparent display, the process and method of spectral color separation also need to make a breakthrough to solve the problem of large size display color difference.

Micro LED transparent display carries more imagination space

Micro LED is regarded as the representative technology of new display technology in the future, what is the combination of Micro LED and transparent display technologies? At present, how is the layout of Micro LED transparent display? Is the technology favored by mainstream manufacturers?

In recent years, Micro LED has become a major hotspot in the development of the display industry, and is regarded as a representative technology of new display technology in the future. Enterprises in the traditional LCD field, LED field and semiconductor field are highly concerned about this technology and actively invest in related technology and product development, but there are not many enterprises that have successfully combined the two technologies of Micro LED and transparent display effectively.

Individual display companies in South Korea and China Taiwan are laying out Micro LED transparent display technology, but technical difficulties and application scenarios are two major constraints to the development of Micro LED transparent display technology. Traditional LCD panel companies, such as Samsung, BOE, CSOT, Cinnabar, etc., with TFT production line technology and glass panel supply chain resources, it is relatively easier to overcome transparent Micro LED technology.

From the enterprise side, the current layout of the technology is more enterprises. For example, the traditional LED display enterprise Vteam is developing transparent Micro LED project. In addition to LED display enterprises, BOE, CSOT and other panel enterprises, as well as some electronic terminal enterprises, such as Samsung, TCL, Konka, Lenovo and so on are also actively participating. In addition, cross-border players such as semiconductors and auto parts are also interested in the technology.

Vteam is making a layout of Micro LED transparent display. Vteam will not only apply Micro LED technology to transparent display, but also apply it to more diversified product areas. On one hand, with the technical advantages of Micro LED, the visual effect of various display products will be upgraded; on the other hand, the continuous cost reduction and quality enhancement of Micro LED technology will help our products to enter into a broader consumer market, and open up a new incremental space for the industry.

What are the advantages of Micro LED transparent display compared to transparent OLED display technology, and in which fields is Micro LED transparent display more suitable for application? What is the judgment on its market trend?

From the display effect point of view, compared with OLED display technology, Micro LED has high transparency, but also has high brightness and high contrast ratio. Micro LED can achieve at least 1,000 nits brightness, and 150,000:1 contrast ratio, while OLED’s brightness is currently at 200-300 nits, which makes Micro LED more suitable for AR and VR products. products. From the perspective of service life and display performance stability, compared with OLED, Micro LED is more stable and has a longer service life, and will not have the problem of image residual shadow after a long time of use, and will not be prone to malfunction or bad spots.

Micro LED transparent display has huge development potential and broad market space, this confidence and judgment comes from two aspects:

First, the technology has a wide range of application scenarios, as long as the life scene has a display application place or the installation of the glass position, can be transparent Micro LED application field. Micro LED transparent display allows glass is no longer just glass, but carries a greater imagination of the display products and content carriers. For example, AR/VR and automotive glass are very suitable for Micro LED transparent display. Through Micro LED transparent display, people can not only watch the content they want to see, but also through the screen, see the real environment outside the screen.

Secondly, as the process continues to mature, production capacity continues to expand, the cost continues to fall, Lazard is expected to promote Micro LED transparent display price performance continues to leap, so as to enter a broader consumer market.

Because LCD can not actively emit light, you need to have a backlight panel of auxiliary lighting to display colorful images, so before the transparent screen on the market is generally only two kinds of OLED and LED.

Compared with transparent OLED, transparent Micro LED is more suitable for engineering display, because the engineering display will be in a fixed area with a long-term unchanged background color or picture text, etc., while the OLED technology uses organic compounds to emit light, and with the passage of time will be left in the display can not be restored branding.

Therefore, transparent OLED has not yet been widely used in engineering products. Micro LED uses micron-sized inorganic diode light-emitting, which makes Micro LED has a high brightness, long life and a wider color gamut space and other technological advantages, and Micro LED uses inorganic light-emitting, long time static screen will not appear burning screen phenomenon.

In addition, the use of OLED environment is generally in -30 ℃ ~ 85 ℃, while Micro LED can work between -100 ℃ ~ 120 ℃, the adaptability of the environment is very high, this feature also makes Micro LED transparent display can be adapted to some special applications, such as automotive glass.

Compared with other transparent display technologies such as OLED, the biggest advantage of Micro LED transparent display is that it can realize high transmittance and high brightness at the same time. The display characteristics of high transmittance and high brightness of Micro LED transparent display are especially suitable for commercial advertisement displays, car displays and other application scenarios. At present several layout Micro LED transparent display enterprises, in the direction of vehicle display has invested a lot of R&D power, transparent Micro LED in the field of vehicle display may have faster growth.

Micro LED transparent display not only has the transparency of glass, but also can realize clear display, such as in the car display, glass windows, financial counters, touch interaction and other aspects of the existence of great application advantages. OLED transparent display although can also realize similar light transmission effect, but limited by the characteristics of the display material, whether product life, luminous brightness or splicing size are inferior to Micro LED products, Micro LED can easily realize ultra-long life, ultra-high brightness and more free large-size splicing.

The market demand for Micro LED transparent display will be significantly increased.

Are there application limitations for Micro LED transparent displays? How to balance the display effect and transparency of Micro LED transparent display?

If Micro LED transparent display needs better transmittance, it will bring lower contrast ratio, for some professional display fields, such as high-end advertisement display and other applications, Micro LED transparent display still can’t satisfy their display needs. To achieve a balance between transparency and display effect is very difficult, high transmittance and high display effect of high contrast itself is a pair of contradictions, need to use the right technology to balance this contradiction.

The effect of Micro LED transparent display is highly susceptible to factors such as background and ambient light, and many display details can not be presented on the transparent display. The simplest and most effective way to balance the effect of Micro LED transparent display and transparency is to carry out adaptive adjustment of different Micro LED brightness under different ambient light brightness conditions to realize the best display effect under different ambient light brightness conditions, and to enhance the display effect while ensuring transparency. In addition, the lines on the glass substrate can be coated with black to enhance the contrast of the substrate itself and the absorption of ambient light without reducing the transmittance rate, thus enhancing the display effect.

Unlike OLED transparent displays, which cannot balance brightness and transparency, Micro LED transparent displays are characterized by brightness and transparency, so there is no need to make trade-offs between brightness and transparency; instead, the most suitable brightness should be selected according to the usage scenario. But Micro LED transparent display is more suitable for large-size applications, because the smaller the size of the product, the more difficult to make transparent, the reason is that not only need to shrink the material, the corresponding glass substrate, circuitry should also be more precise, now this part of the ability to continue to improve.

Manufacturers in the balance of Micro LED transparent display display effect and transparency, generally according to the application of different applications to choose different substrates, so as to adjust the proportion of transparency and contrast. For example, Tianma has launched two transparent screens for automotive applications and a semi-transparent screen with a light gray substrate. In addition, pixel density also affects transparency; the higher the pixel density, the higher the picture quality, but the transparency will be reduced. However, vehicle displays, glass windows, financial counters, and touch interaction are applications that generally do not have too demanding requirements for picture quality, and can appropriately sacrifice contrast, brightness, and color saturation.

When Micro LED transparent display terminal products in the major consumer electronics exhibition frequently debut, whether it is a sign of “transparent display” of the exclusive era is coming? How far away from the Micro LED transparent display market demand explosion there is still much road to go?

Micro LED technology itself is still in the development stage, process, reliability, cost and many other issues need to be resolved. Micro LED transparent display as micro LED technology innovation products, although there are unique display characteristics, but its scope of application still has certain limitations. To become a universal product, its technical maturity, reliability and cost are still to be improved.

The biggest limitation of Micro LED transparent display currently exists is still the cost issue, which is also a major bottleneck restricting the development of Micro LED display technology. As more and more manufacturers enter the Micro LED transparent display, the technology will become more and more mature, and the market volume will become larger and larger, and consequently the cost will fall. It is expected that the next three to five years will be the outbreak of transparent Micro LED.

Micro LED transparent display technology chain can be divided into chip-side technology, common technology, equipment technology, and display-side technology four categories, these four types of technology have roadblocks, and Micro LED is also facing OLED such a strong competitor. Terminal manufacturers will generally favor the direction of technology with more stability in mass production.

At present, the manufacturers have only displayed Micro LED transparent display samples, the market has not been a batch of products shipped. Micro LED transparent display market outbreak needs a process, so that it can be widely accepted, stable quality, affordable products, rather than high-end customized products. At present, a number of manufacturers have set the mass production of Micro LED in 2027, which is also expected to become the mass production node of Micro LED transparent display. By then, Micro LED transparent display will definitely bring people refreshing visual products, and its figure will appear in different scenarios such as family, automobile, showroom and shopping mall.

Whether the demand of Micro LED transparent display market can be exploded mainly depends on the maturity of the technology as well as the cost reduction. On the one hand, it is necessary to break through the bottlenecks of TFT glass substrate technology, giant transfer technology, etc. These technical problems will take at least 3 more years to be gradually solved;

On the other hand, Micro LED transparent display is limited by product yield problems can not be mass production, product costs are currently high. In the future, the maturity of the technology will promote the decline of product cost, when Micro LED transparent display will find its own place in the field of reality.

The outbreak of Micro LED transparent display market demand is still more limited by Micro LED technology itself. It is believed that with the development of Micro LED technology, the size of Micro LED chips will become smaller and smaller, and the glass substrate technology will become more mature, coupled with the TFT technology, light-driven technology, etc., the technological upgrading process of Micro LED transparent display will be accelerated. It is expected that in the next three to five years, the market demand for Micro LED transparent display will be significantly increased.