Techlion Display

LCD Module Manufacturer

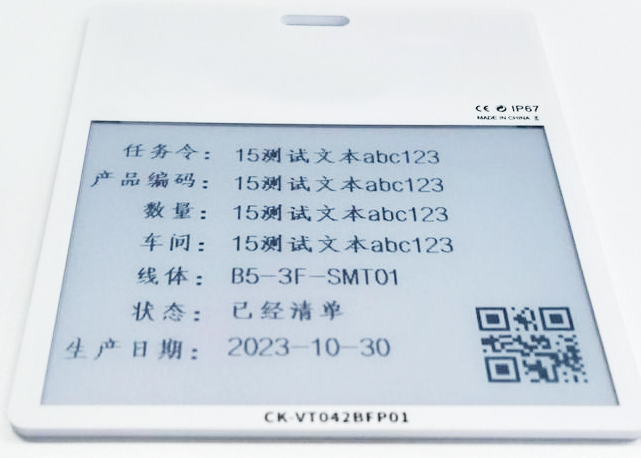

Industrial flow box evolution: a passive RFID e-paper ink screen tags

With the continuous development of science and technology, passive ink screen as a new type of display technology, is gradually being used in various fields. Among them, the application of industrial flow box is particularly prominent. Industrial flow box is an indispensable tool in industrial production, used for the transportation and storage of goods. The traditional industrial flow of the box generally in order to show the name of the items in the box will print the name of the item data to the paper and then pasted in the industrial flow of the box for staff to identify, but this traditional paper has certain defects:

1, easy to break, resulting in missing content;

2, each flow box flow need to determine the completion of the item information, and then handed over to the printing staff will print the data to flow again, flow time becomes longer can not update the information in a timely manner;

3, each piece of paper is only used once, need to be discarded after use, accumulated every year there is a large amount of paper waste.

And passive RFID electronic paper screen as industrial flow box on the display, can provide staff with more convenient and efficient operation experience.

Solution Case

Passive RFID e-paper ink screen is a kind of e-paper display technology, also known as e-ink screen. It has such advantages as high reflectivity, low power consumption, high contrast, wide viewing angle, etc. The principle of passive ink screen is mainly electrophoretic display technology, and its basic composition is a display component that contains two substrates, one of which is a transparent conductive film, and the other is coated with a black particle film. Between the two substrates filled with positively and negatively charged white and black particles, by changing the charge so that the particles of different colors are arranged in an orderly manner, thus presenting a black-and-white or color display effect. The display effect of ink screen is clear and natural, which can meet the needs of various application scenarios.

Passive RFID e-paper in industrial flow box applications:

1, item information display: the use of passive ink screen on the industrial flow box, you can display the name of the item, the number, destination and other information. Staff can check the information by viewing the display to ensure the accurate transportation and storage of items. At the same time, through the use of passive ink screen, you can avoid the traditional paper labels are easily damaged, fuzzy and other problems, to provide a more reliable way of displaying information.

2、Special goods identification: when transporting dangerous goods, fragile goods and other special goods in the industrial flow box, the use of passive ink screen can clearly identify the name of the goods, quantity, destination and other information. At the same time, it can also mark the corresponding safety operation guidelines and precautions to improve the staff’s safety awareness and operation level.

3, inventory management: through the passive RFID electronic paper screen installed in the industrial flow box, you can realize the real-time management of inventory. Staff can view the inventory quantity and item information on the ink screen, replenish the stock in time to avoid inventory backlog and waste.

4, modify the content of the convenient: production line workers can directly modify the content of the ink screen through the handheld, no need to reprint fast and convenient, reduce process steps, improve efficiency.