Techlion’s Robust Quality Control System in LCD Manufacturing

| Size | |

| Display Technology | |

| Resolution | |

| Interface | |

| Luminance | |

| Outline Dimension | |

| Active Area | |

| Viewing Angle | |

| Model Name | |

| Operation Tmperature | |

| Storage Temperature | |

| Shape Type |

In the ever-evolving landscape of LCD manufacturing, precision and reliability are non-negotiable. At Techlion, we recognize the paramount importance of delivering LCD products of the highest quality to our customers. Our commitment to excellence is fortified by a comprehensive and robust quality control system that ensures each product leaving our factory meets and exceeds industry standards.

Contents

Experienced Workforce:

At the core of our quality control system is a team of highly experienced and skilled workers who bring a wealth of expertise to the manufacturing process. Our workforce is not just a collection of individuals; it is a cohesive unit with a shared commitment to craftsmanship and precision. With a wealth of experience, our workers understand the nuances of LCD manufacturing, contributing to the consistent quality of our products.

Stringent Quality Control Measures:

Our commitment to quality is embedded in every step of our manufacturing process. We have implemented stringent quality control measures to monitor and evaluate each stage, from the selection of raw materials to the final assembly of LCD products. Our quality control system is designed to identify and rectify any deviations from the specified standards promptly.

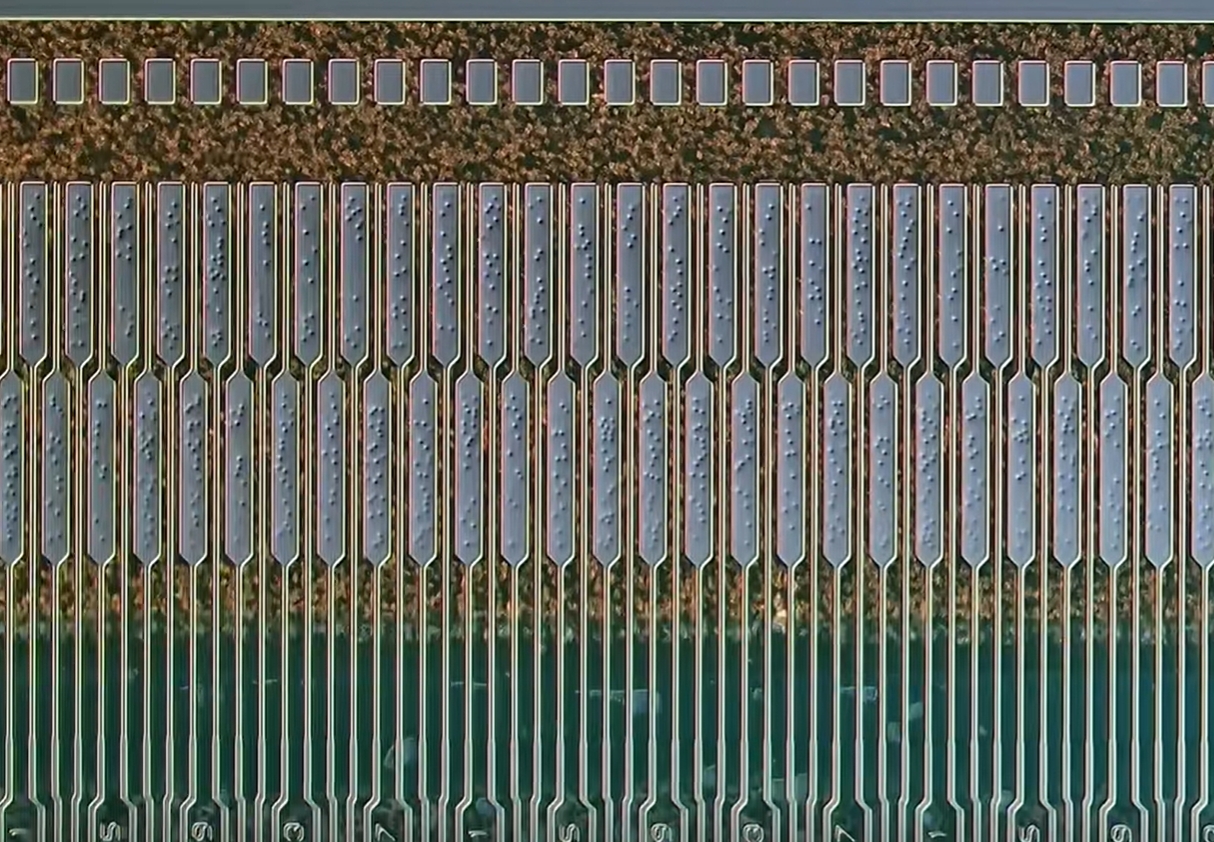

State-of-the-Art Testing Facilities:

To ensure the reliability and performance of our LCDs, we have invested in state-of-the-art testing facilities. Our testing processes encompass a range of parameters, including visual inspection, functionality testing, durability testing, and performance assessments. These rigorous tests are conducted to guarantee that our products meet the highest industry benchmarks.

Comprehensive Inspection Protocols:

Every LCD that rolls off our production line undergoes comprehensive inspections. Our quality control team meticulously examines each unit for any defects, inconsistencies, or imperfections. This attention to detail allows us to identify and rectify issues before the products reach our customers, ensuring that only top-tier LCDs are shipped.

Traceability and Accountability:

Our quality control system incorporates traceability and accountability measures. Each product is assigned a unique identifier, allowing us to trace its journey through the manufacturing process. This traceability ensures that, in the rare instance of a quality concern, we can swiftly identify and address the issue, providing our customers with transparent and accountable solutions.

Continuous Improvement Culture:

At Techlion, we believe in the philosophy of continuous improvement. Our quality control system is not static; it evolves with advancements in technology and industry best practices. We actively seek feedback from customers, monitor industry trends, and implement changes to enhance our processes, ensuring that our quality control system remains at the forefront of LCD manufacturing standards.

Customer Satisfaction Guarantee:

The ultimate goal of our quality control system is to guarantee customer satisfaction. By adhering to the highest standards of quality, we instill confidence in our customers that the LCD products they receive from Techlion are reliable, durable, and meet or exceed their expectations.

In conclusion, Techlion takes immense pride in our comprehensive quality control system, which stands as a testament to our commitment to excellence in LCD manufacturing. With an experienced workforce, stringent control measures, state-of-the-art testing facilities, and a culture of continuous improvement, we assure our customers that every LCD product is crafted with precision and delivered with confidence. As we continue to advance in the LCD manufacturing industry, our quality control system remains a cornerstone of our success and a guarantee of customer satisfaction.